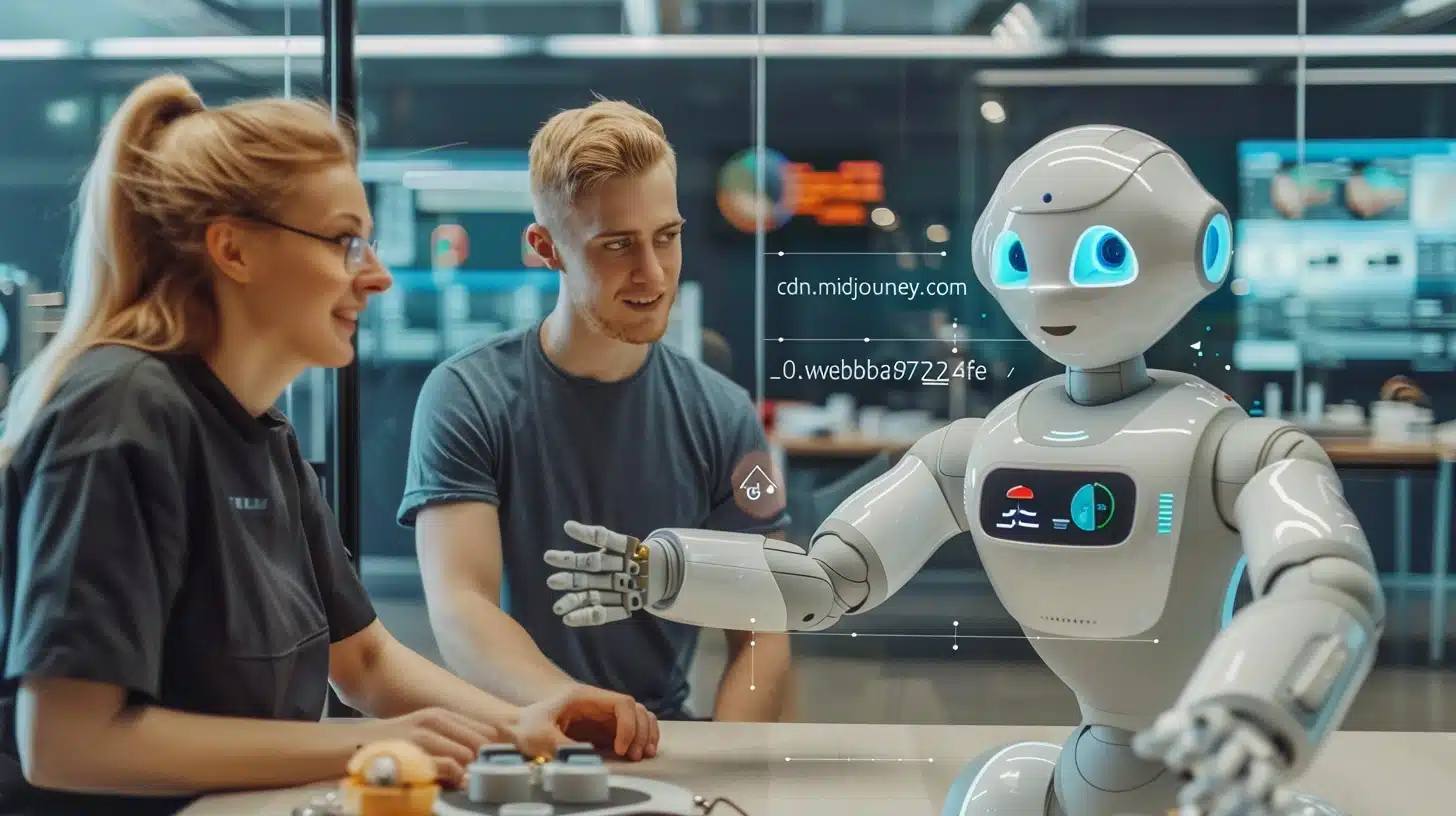

Workplace automation is changing, and collaborative robots (cobots) are leading the way. Unlike traditional industrial robots that need safety cages, cobots are designed to work safely alongside humans in shared spaces. They can handle repetitive or physically demanding tasks, reduce the risk of injuries, and improve productivity. In this guide, we will explain how cobots work, their main benefits, and why they are becoming essential in modern industries.

How Collaborative Robots Work

Collaborative robots, or cobots, are designed to work safely alongside humans in shared workspaces. Unlike traditional industrial robots that operate alone behind safety barriers, cobots can perform tasks right next to people without risk of injury, thanks to their advanced safety features.

Core Components

Robot Arms: Mechanical arms that can pick, place, or assemble parts.

Sensors: Detect the environment and human presence using cameras, force sensors, and proximity detectors.

Control Software: Acts as the robot’s brain, processing sensor data and controlling movements.

End Effectors: Tools attached to the arm, like grippers, suction cups, or welding torches, to interact with objects.

Programming and Operation

Cobots are easy to program and operate using different methods:

Teach Pendants: Handheld devices that let operators guide a robot’s movements, which the robot then remembers and repeats automatically.

Hand-Guiding (FreeDrive): Operators physically move the robot to desired positions, and the robot records the path.

Intuitive Interfaces: Touchscreens with haptic feedback make programming simple and require little training.

Safety Features

Cobots include multiple safety mechanisms so they can work safely alongside humans:

Force and Power Limiting: Cobots detect and limit the force they apply to avoid injuries.

Collision Detection: Sensors detect unexpected bumps and stop or adjust movement.

Speed and Separation Monitoring: Cobots move faster when no humans are nearby and slow down when someone enters their workspace.

Cobots use advanced technology and built-in safety features to work alongside people, increasing both productivity and safety.

Key Benefits of Collaborative Robots

Cobots help people work faster, safer, and more efficiently in many industries. They are made to work safely alongside humans, making them useful in modern factories and logistics.

Quick Setup and Easy Programming

Cobots are simple to install and program, often ready to work within hours without special training. This allows businesses to add automation quickly and adapt easily to changing needs.

Safer Workplaces

Cobots are equipped with safety features like force sensors and collision detection, enabling them to work safely alongside people. This helps prevent injuries and creates a safer workplace.

Flexible and Adaptable

Cobots can be quickly reprogrammed for different tasks and easily moved between production lines, making them ideal for operations that frequently change or require customized work.

Higher Productivity and Consistency

Cobots take on repetitive or time consuming tasks, boosting efficiency and ensuring consistent quality. Their accuracy minimizes errors and accelerates production.

Cost-Effective

Cobots are more affordable than traditional industrial robots. They require less maintenance and don’t need expensive safety infrastructure, making them ideal for small and medium-sized businesses.

Better Worker Morale

Cobots take over boring or physically demanding tasks, allowing humans to focus on more interesting and valuable work. This increases job satisfaction and creates a more engaging workplace.

Cobots provide safer, faster, and more efficient ways to work. Their flexibility, ease of use, and cost-effectiveness make them an essential part of modern manufacturing, logistics, and other industries.

Applications of Collaborative Robots

Cobots are flexible, precise, and safe robots that can work alongside humans. They are increasingly used across industries because they improve efficiency, reduce errors, and take over tasks that are repetitive, dangerous, or physically demanding.

Machine Tending and Assembly

Cobots assist in manufacturing by handling machines and assembly tasks:

Machine Tending: They load and unload materials into machines like CNC machines, presses, or injection molding machines. This speeds up production while reducing the risk of injury in dangerous areas.

Assembly: Cobots can assemble products with high precision, such as electronic components, automotive parts, or delicate medical devices. Their consistent accuracy reduces mistakes and ensures quality.

Quality Inspection and Material Handling

Cobots help maintain high-quality standards and manage materials efficiently:

Quality Inspection: Cobots employ cameras and sensors to detect defects, measure parts, and ensure products meet quality standards.

Material Handling: Cobots assist with tasks such as sorting, packaging, and moving items on and off pallets. This decreases physical strain on workers, accelerates workflow, and guarantees consistent handling of products.

Benefits Across Industries

Electronics: Precise component placement, screw driving, labeling.

Food & Beverage: Packaging, labeling, and machine operation in hygienic environments.

Pharmaceuticals: Packaging, labeling, quality control, ensuring safety and compliance.

Aerospace: Assembly of delicate components, inspection for defects, maintaining safety, and quality standards.

Cobots are safe, flexible robots that boost productivity and protect workers. They handle precise, fast, and reliable tasks and are used in many industries, including manufacturing, logistics, healthcare, and aerospace.

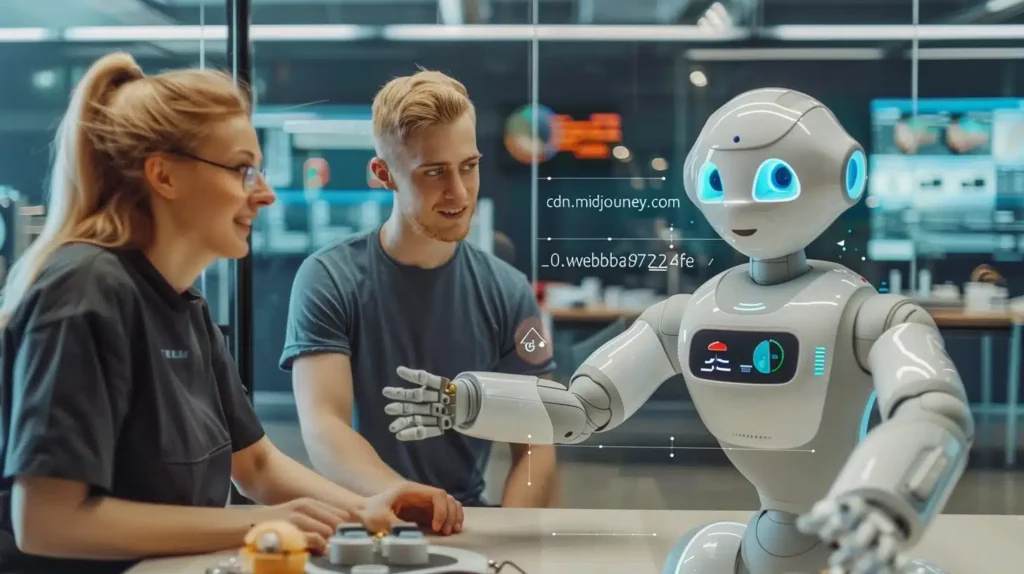

How Collaborative Robots (Cobots) Help Human Workers

Collaborative robots, or cobots, work alongside humans to make jobs easier and safer rather than replacing them. They bring several benefits that support and empower workers in different industries:

Freeing Workers for More Important Tasks

Cobots take on repetitive or simple tasks like machine tending, assembly, and packaging. This frees human workers to focus on complex and valuable work, such as quality checks, problem-solving, and process improvements. By managing routine jobs, cobots help workers become more productive, engaged, and satisfied.

Helping with Labor Shortages

Many industries, especially manufacturing, face a shortage of skilled workers. Cobots can work continuously without getting tired, filling gaps in the workforce, and keeping production running smoothly. This is especially helpful in areas where many positions remain unfilled, ensuring companies can meet demand.

Promoting Skill Development

Working with cobots helps employees learn how to program, operate, and maintain robots. This helps them adapt to automation, advance their careers, and get ready for future opportunities in robotics.

Cobots assist human workers by handling repetitive tasks, filling in during labor shortages, and helping employees develop new skills. By working alongside humans, cobots make the workplace safer, more efficient, and more satisfying.

Best Practices for Using Collaborative Robots (Cobots)

Adding cobots to your workplace can make work safer and faster, but it needs careful planning. Here are some simple steps to use cobots effectively:

Identify Tasks That Need Support

Focus on tasks that are repetitive, physically demanding, or require high precision. Ask employees which tasks are tiring or difficult to find out where cobots can help the most.

Prioritize Safety

Keep cobots safe by using sensors, collision detection, and emergency stops, and by regularly reviewing workflows to prevent accidents.

Choose the Right Cobot

Select a cobot that matches your needs by evaluating its payload, reach, speed, and precision, and make sure it fits seamlessly into your existing workflow.

Train Your Team

Provide proper training on how to operate cobots safely. Teach emergency procedures and how to collaborate effectively with the robots. Skilled staff ensure safe and smooth operations.

Monitor and Improve

Track cobot performance and gather feedback from workers. Use this information to make improvements and maintain efficient workflows.

Following these steps helps cobots work safely and effectively, improving productivity, efficiency, and worker satisfaction.